How To Clean Dirty Soldering Iron Tip

To apply the tip cleaner first heat the soldering iron.

How to clean dirty soldering iron tip. Ive been using a Hakko 936 soldering station since October now through many projects and the tip is still very intact almost as good as new. Cleaning the iron is usually done with either a damp sponge or brass turnings. Cardboard works in a pinch.

Avoid using low-residue flux or dirty flux. Wipe OFF the solder on the Cleaning Sponge or Copper Wool. Alternatively you can use a special polishing bar particularly of.

Just rub the soldering iron tip on it after each solder. Then dip the tip in the cleaner and do a slight twist action. Flood the tip with solder after cleaning to cover the entire working surface of the tip.

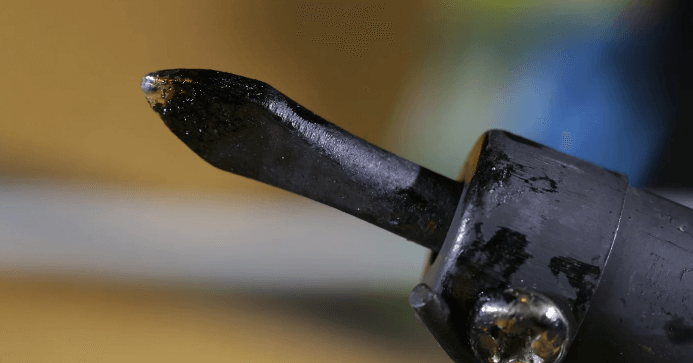

If the tip is a little too dirty you can apply a cleaning paste and a tip tinner. Another option is to use tip cleaner. Heat your soldering iron up to the low end of a typical work range generally between 280 and 320C.

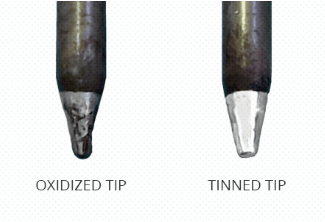

Once clean and shiny perform tinning and now your tool is ready to use. Use dampened steel wool to get rid of surface stains or rust. Maintaining the right operating temperature ie 320 C.

Electronix Express points out that in order to remove the dirt and debris that accumulates on the tip of a soldering iron it is necessary to wipe it clean with a sponge. If some of the oxides are just sticking really well you could try to mildly abrade them on a brass sponge copper braid or similar but you cant be too hard or you will damage the iron plating good tips are typically copper core plated with iron then chromium everywhere but the. Push the soldering iron tip into the chemical cleaner until the entire rusted area is submerged.