How To Fix A Broken Soldering Tip

If that gives you sound it means you lost connectivity while soldering the ground and you will need to heat up the solder and remove it with the solder pump or wick.

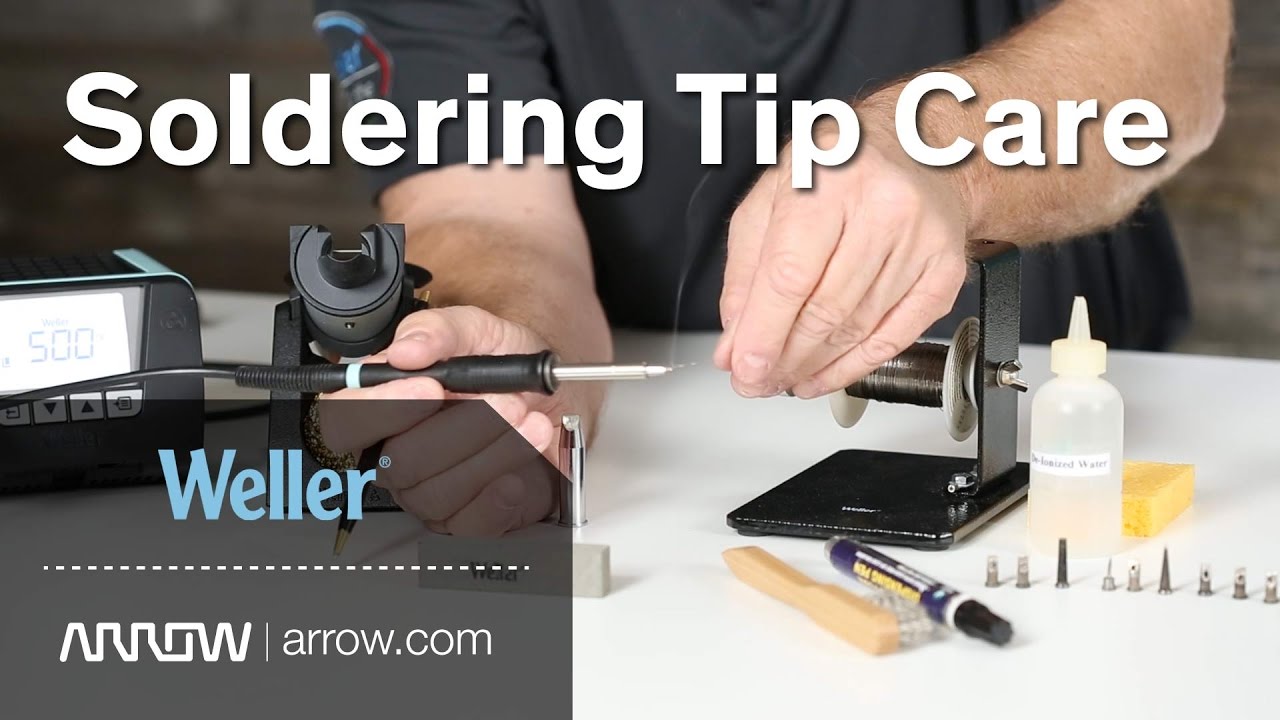

How to fix a broken soldering tip. You must have a steady grip on your iron to attach the wire. Once you have all your wires soldered to the plug and youve tested it to make sure everything is working you should pat yourself on the back. Get your soldering iron really hot wipe some fresh solder onto the tip and wipe it off again by drawing the tip across a damp sponge this cleans or tins the tip.

Otherwise the Soldering Tip may Break. Open the Soldering Iron Carefully. This trick simplifies the soldering process and enables the goldsmith to do better work faster and with fewer mistakes.

Using a sponge will help to keep the soldering iron tip clean by removing the oxidation that forms. I usually go with a 30 awg roll. Female RCA plug also.

Tips with oxidation will tend to turn black and not accept solder as it did when it was new. To repair an overheated joint you should carefully scrape the joint with the tip of a knife or use isopropyl alcohol and a toothbrush to remove the burnt flux. Distribute the liquefied plastic smoothly along the length of the seam with soldering iron tip.

Since the move from lead to lead-free solders a common complaint has been short tip life. Best to clean the tip again and then apply some Solder directly to the tip. If the plug is cooled down pull out spout and the coupling to the plug replace the plastic guide and screw on the plug.

If playback doesnt begin shortly try restarting your device. If it doesnt you need to remove all solder and grind the tip again more thoroughly. Repairing Soldering Iron Tips.