How To Fix Oxidized Solder Tip

Use brass wool or specially designed cleaners on the tip.

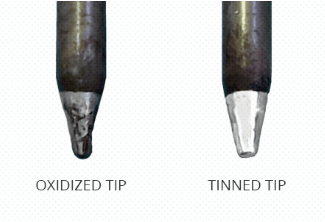

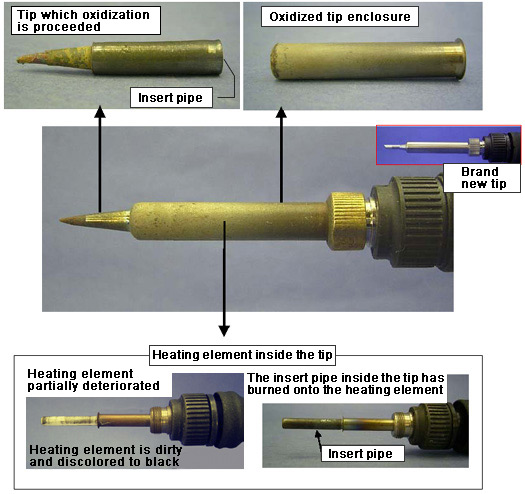

How to fix oxidized solder tip. Good soldering process is important. Please note that the FS-100 should not be used for other purposes apart from restoring the soldering tip. The tip gets black and solder is not sticking to it anymore.

Therefore it is advisable to use the dry cleaner options to avoid shock do a faster job and increase the life of the iron tip. This should leave the tip of the iron with a layer of solder on it. With the iron tip cold use a polishing bar.

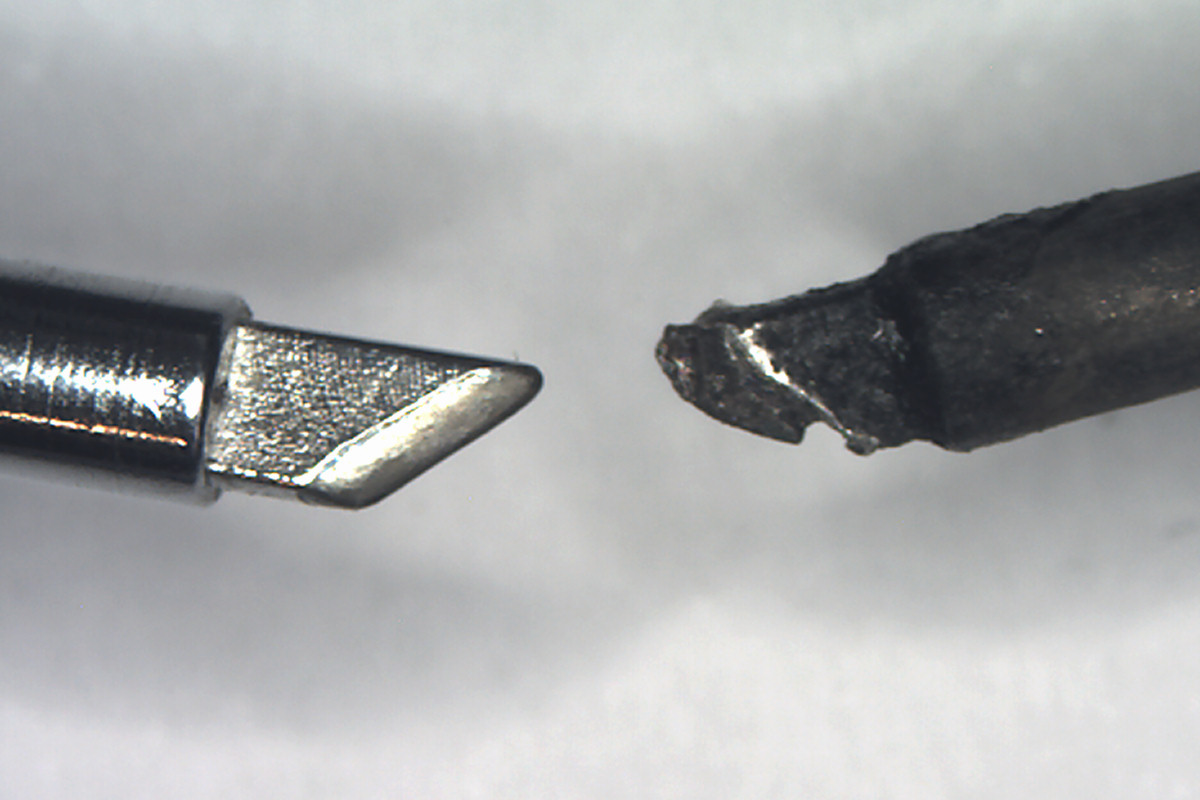

For that use resin-layered cardboard. Extended use of soldering tips at high temperatures can easily lead to oxidation. Repeat steps 2 and 3 until the oxidation has been completely removed and the tip shows a good wetting on all its working.

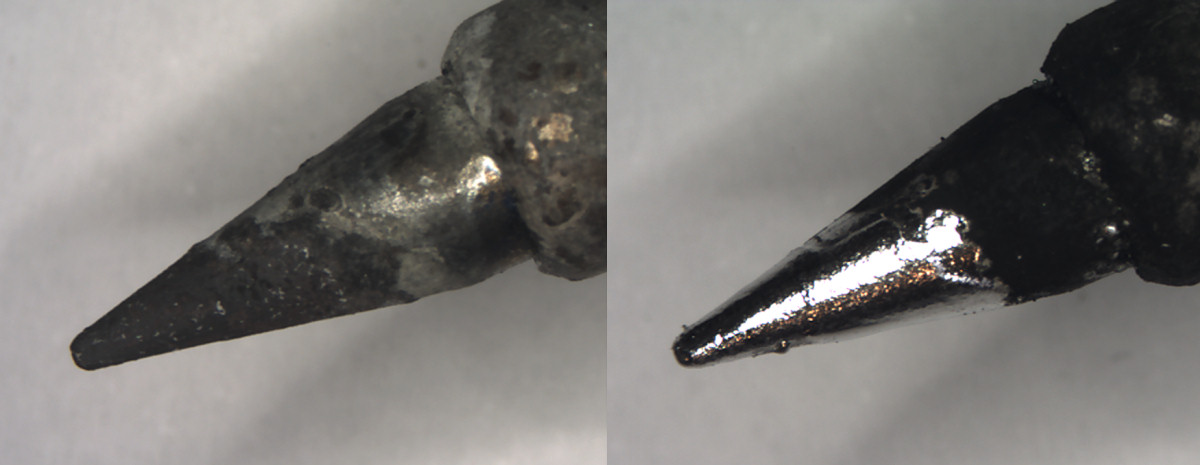

It took a lot of effort with tip tinnercleaning compound to make the solder wet the tip again. You can also use resin. You need to rub the tip on the block while rotating it.

Overheating the tip Your soldering iron should be set to 100C of the solders melting point. In addition a heavy oxide can be formed on the pipe itself preventing a bond from forming between the filler metal and the pipe surface. A polyurethane foam bar with embedded abrasives which is used to polish the working end of the tip to remove surface oxides.

You can remove oxides easier by wiping the soldering iron tip in a wet sponge. Repeat the steps above until the tip is clean. Solder tips get oxidized over time.