How To Improve My Tig Welding

For the beginner it may be a very intimidating process.

How to improve my tig welding. TIG is suitable for welding in titanium copper among others and it is an incredible application that is suitable for tricky welds. TIG generates heat via an arc of electricity jumping from a tungsten metal electrode to the metal surfaces you intend to weld - usually aluminum. Use clean dry filler rod.

Like other kinds of welding TIG welding involves high heat and intense light. Im 14 and just started I keep my auto-darkening helmet to go to around shade 10 in dark-state and I dont know what Im doing wrong to not be able to see the weld puddle that is present during welding. Tungsten Inert Gas welding is another type of welding that you can try out.

Hold the rod so it rests horizontally at approximately a 15-degree angle to the workpiece. Make sure your rod is clean and dry. S-curves or welds on round things.

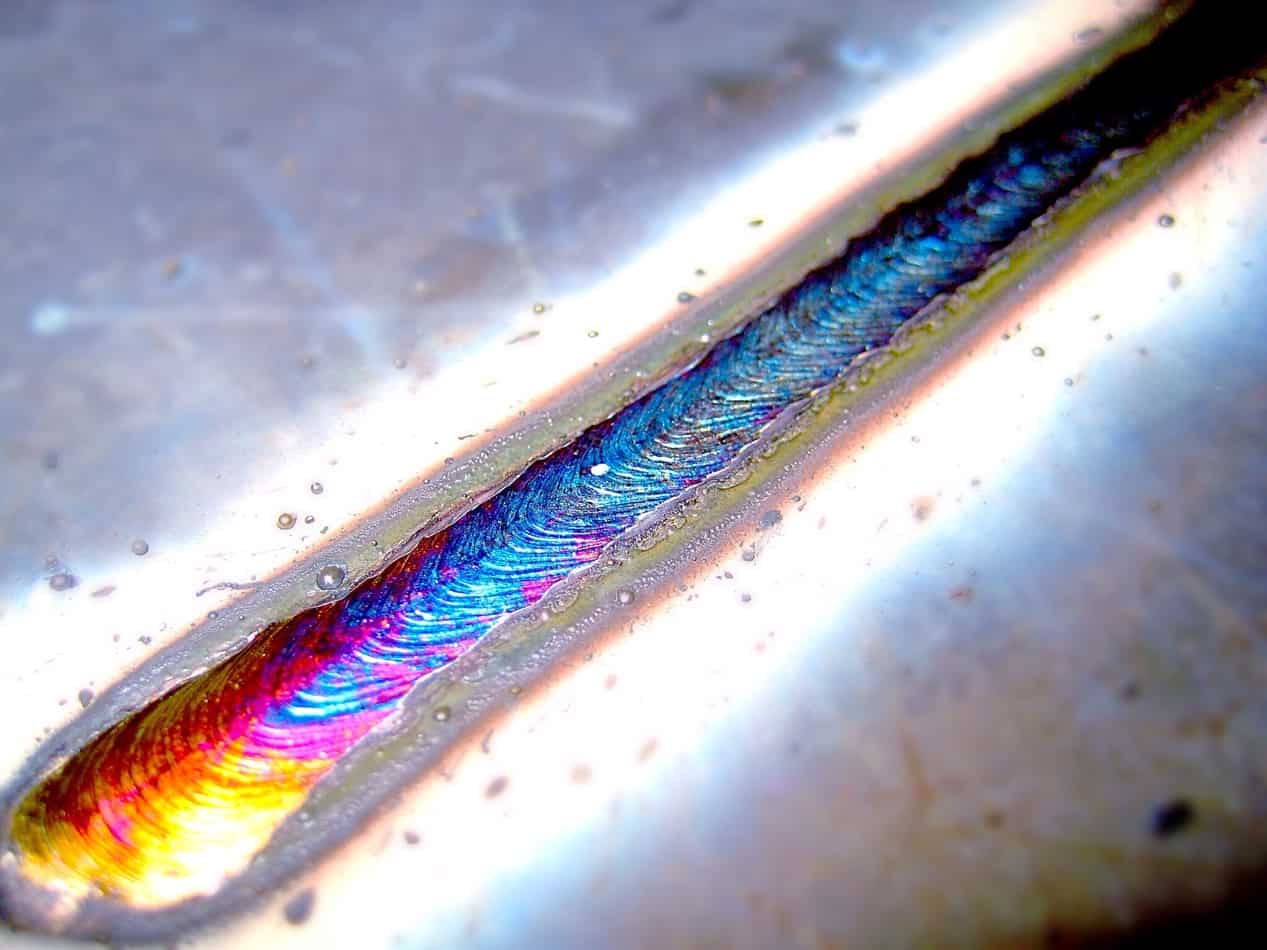

Tig welding can produce beautiful looking welds and more importantly x-ray quality deposits on some of the most critical welding applications. Gently but quickly dab the filler metal in the weld pool after heating up the. If it is at all possible use gas lens as they will improve shielding gas coverage as well as offer you better joint accessibility which should greatly improve your TIG welding efficiency.

No matter what field youre in from pipe welding to prototype fabrication there is going to come a time when a joint is going to require you to weld. These lenses evenly distributes gas to help in the prevention of oxygen contamination as well as allow you to properly work in those heard-to-reach areas like the K T and Y joints. Often you can rest your wrists on the part being welded.

Invert the process. It will weld another and easier. TIG welding requires proper shape for the electrode tip.