How To Improve Soldering Process

Tinning will also help to protect the tip and reduce wear.

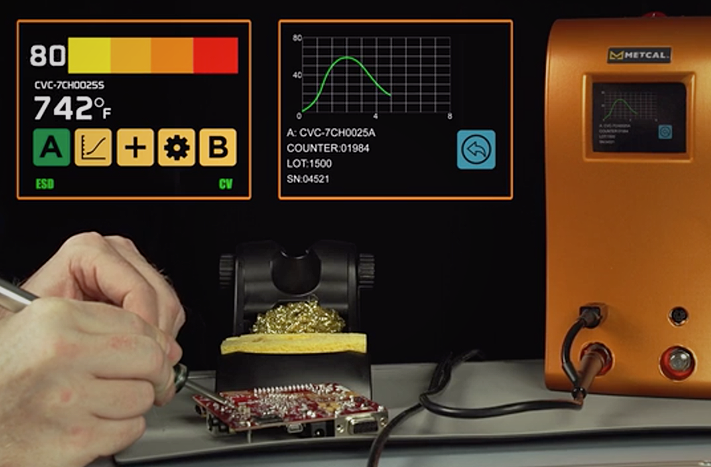

How to improve soldering process. To change the amount of solder paste of the BGA you can start from Stencil. If the soldering iron tip isnt responding to the extra solder revive dirty. A clean and tinned soldering tip conducts heat through the desoldering braid better and starts the wicking action faster.

The use of the correct solder solder flux and avoiding oxidation are all important components of the soldering process. Quality solder joints are a combination of proper technique as well as proper soldering. After prolonged use the tip will become dirty which will make the soldering process difficult.

Reduce conveyor speed to increase solder contact time Increase flux volume applied reduce air knife pressure Use more active flux systems such. Involves preheating fluxing soldering using a wave of solder cleaning and quality. The basic principle is to make the amount of solder ball printed in the outermost row or four corners of the BGA more than that of the remaining solder balls.

Density component type. Enhance the board strength. Thermal shocks occur when the temperature rises suddenly.

Preheating of PCBs is done using hot air heaters. This process will help improve the heat transfer from the iron to the item youre soldering. Tinning also helps protect the tip and reduce wear.

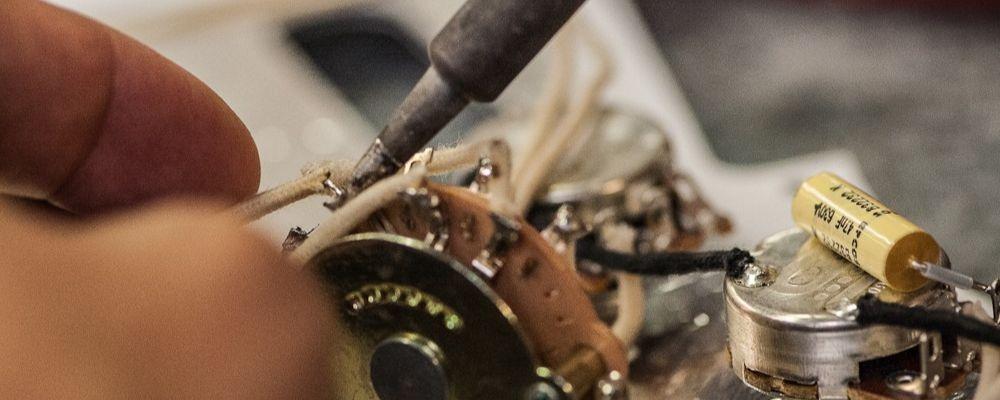

Good soldering is influenced by how clean the tip of your soldering iron is. This process helps to improve the heat transfer from the iron to the object to be soldered. Before you can start soldering you need to prep your soldering iron by tinning the tip with solder.