How To Make A Soldering Iron Out Of Household Items

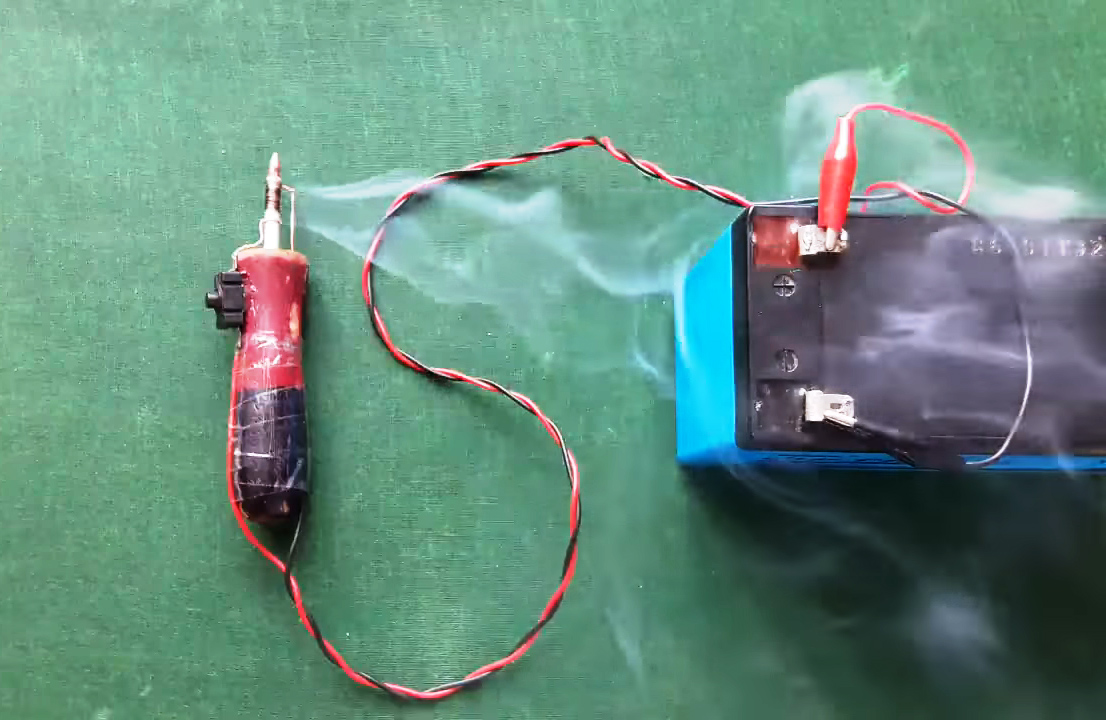

Take any items that might be flammable out of the area where you are working.

How to make a soldering iron out of household items. It sucks the solder away from the solder joint. The panels about 5 tall 9 long with a 45 degree angle cut as shown. The solder sucker or solder pump is a mechanical vacuum pump.

I chose this inclination because it was easy to work with provided a fairly comfortable angle at which to replace the soldering iron. Step 1 Place a piece of the desoldering braid on top of the jointsolder you want removed. Rosin is the same organic material as flux so it is already built into the solder.

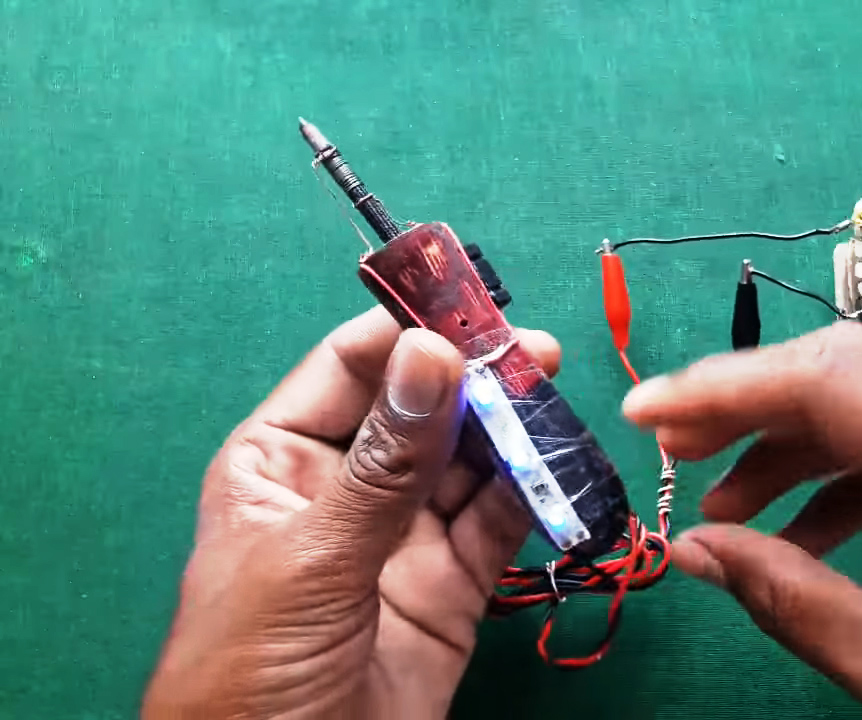

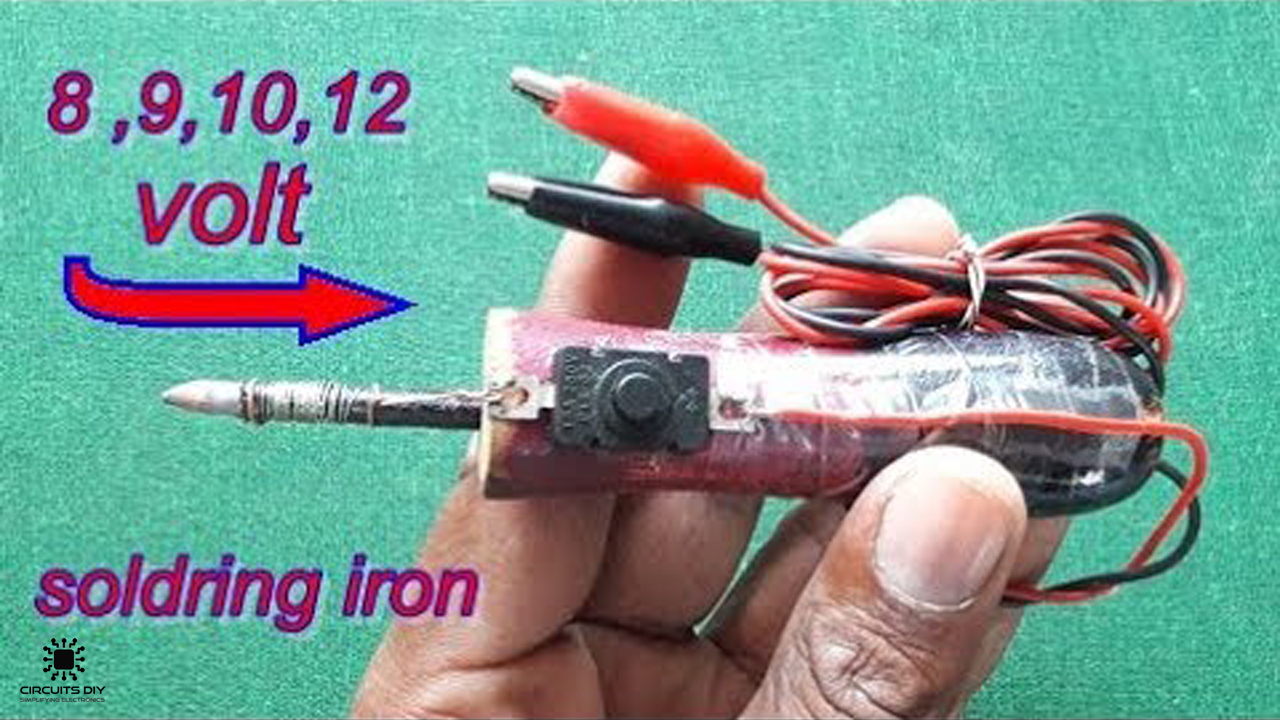

Soldering involves allowing the heated tip of the iron to reach very high temperatures before using it to melt the solder wire around the components that will be soldered. The solder sucker and the solder wick. Tighten the nut with the spanner wrench.

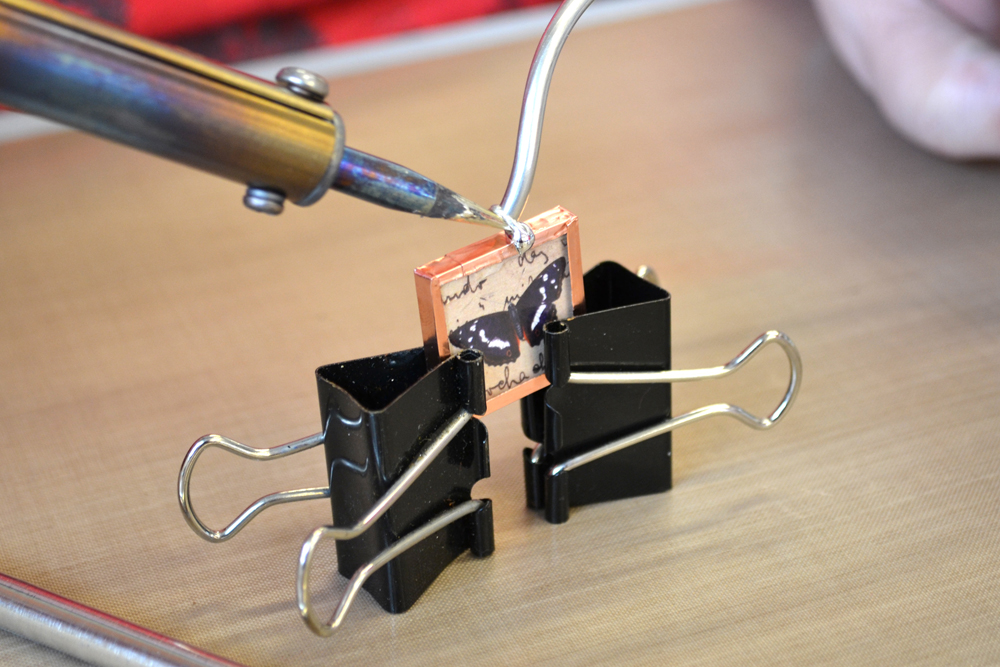

Acid core solder will also clear metal surfaces of. This will heat the solder below which will then be absorbed into the desoldering braid. Separate the two leads at the end of the replacement heating element with your fingers.

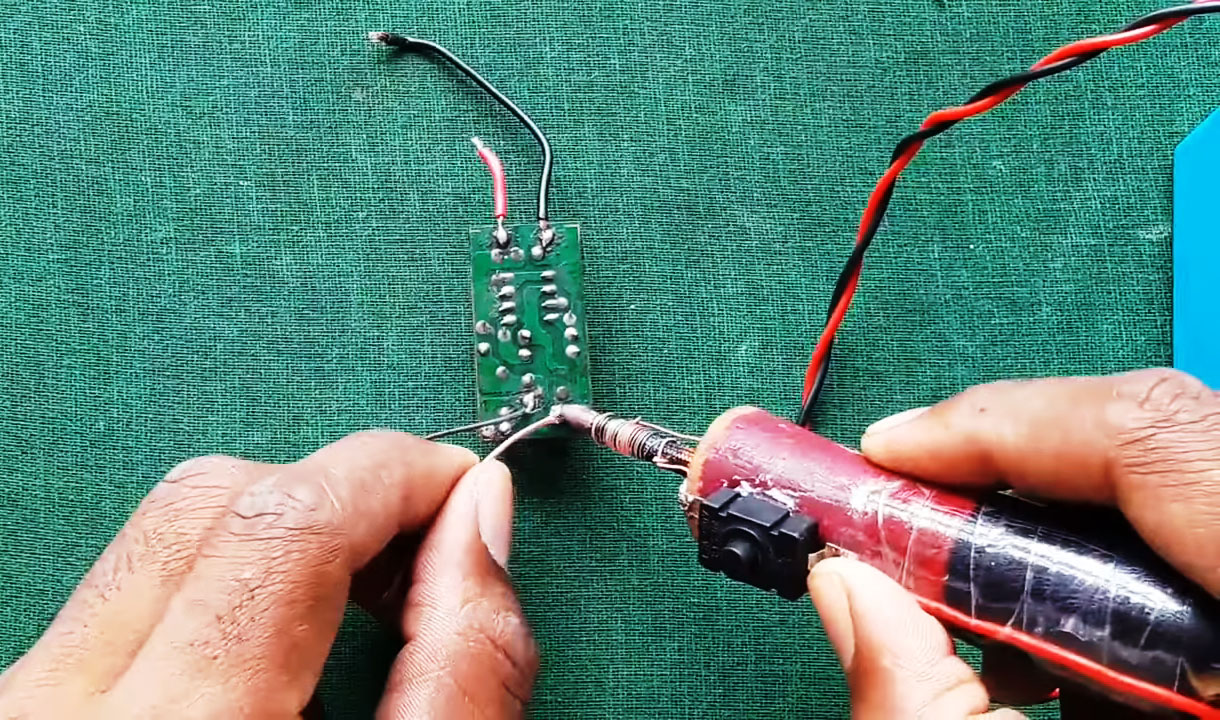

Insert the two leads at the end of the replacement heating element into the two connectors of the soldering iron. The solder will clean the surface as it melts. Use a good overhead light to shine over your workspace.

As it cools back to room temperature the bond will solidify and become permanent - at least until it is desoldered. Youll see the solder soak into the wires around the point where your iron is touching once it gets hot enough to melt. The good news is that most modern solder is made with a rosin core.