How To Prepare Soldering Flux

The tinplate metal you want to solder may need some preparation before its ready.

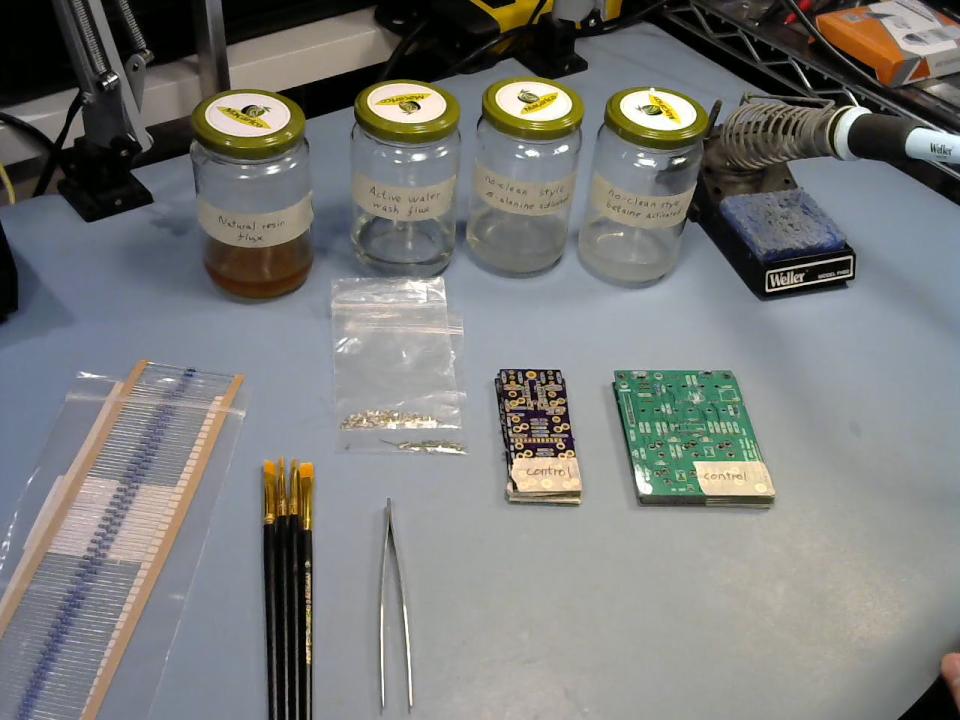

How to prepare soldering flux. Flux will help to remove any deposited oxides from the surface of the metals thus leading to better joints. Push the soldering gun onto a side of your wires to melt flux. Before you start soldering ensure your materials and hands are clean of oils and grease.

Flux is a wonderful goo that makes soldering faster and easier. Got home and realized it doesnt mention rosin anywhere on the package and neither does the online listing. Well get you started and dont miss the giveaway at the end of the video.

It helps to clean and remove oxides and other impurities and thus helps in wetting. Once you are ready with the flux cleaning solution know that the rest of the procedure of how to clean PCB after soldering is only a matter of time. Step 2- Using a brush apply flux with solder to both pieces of the terminal that need to be connected.

The remaining flux left in the dish can be used again using a little bit of water. How to make soldering flux with rosin and alcohol. The citric acid flux you have made can now be used to prepare metal for soldering.

Do not touch it. Cleaning the flux residue. Hold the soldering iron properly in one hand and the wire in the other hand.

You can use a flux pen to dispense flux. Solder flux is a kind of chemical used in Automatic PCB Assembly and Hand Soldering. Cut the cone leaves and place them in a container then pour the alcohol over the leaves and let them sit overnight.