How To Solder Boat Trailer Wires

Solder wires cover with shrink tubing.

How to solder boat trailer wires. Trailer wiring isnt all that complicated but most of us dont have electrical engineering degrees either. Remove them and splice them using proper crimp-type butt splices or bare the wires place heat shring tubing over the wires join the splice solder and then shrink the tubing over the splice. Use hi quality materialsrun it thru conduit in side the frame railssoilder connections and on the rear lights mnt a flat plate in front of the lights and wires to keep snow and spray off lights and wiresMy trailer has 10 yrs on itpulled every weekend of the first 6 yrsand I am finally having issues with a light plug or twoalso use dielectric grease on all bulb sockets and connectorsincluding truck.

Two types of a trailer wiring tester. The best way to secure a ground to a trailer or any metal surface is to do exactly what you described. Just get the right size ring terminals and thread you big wires thru the connector then crimp all the wires with the right size.

And the scheduled departure is in five minutes. Then drill a hole in the surface you want to attach the ground to. Run the tip of the solder on top of the wire so it melts into the wires.

This is a bare non-insulated B or F type crimp terminal. To answer you question though - you do not have to bare the wires using the blue junk splicers. Hook up your trailer and connect the trailer light harness.

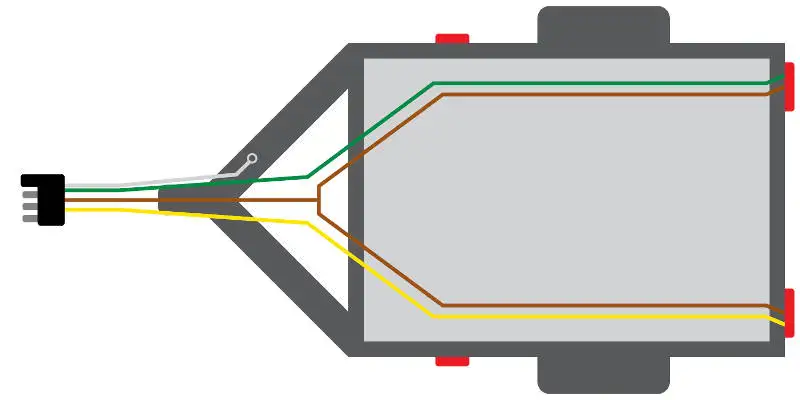

Run the Wires Boating Magazine. It may be necessary to run the wires inside a tubular frame member or rings along the frame. Have a helper stand back to see if the running lights stoplights and blinkers are working properly.

I rewire all of my trailers with the plastic 7 way connectors. Joined Jul 22 2014 424 Posts. Then take the two ends and push then directly into each other.