How To Solder Car Speaker Wire

Another person said tinning would reduce conductivity and to simply screw down the naked wire into a screw type connector using a banana plug and put some silicone sealant over the finished connector.

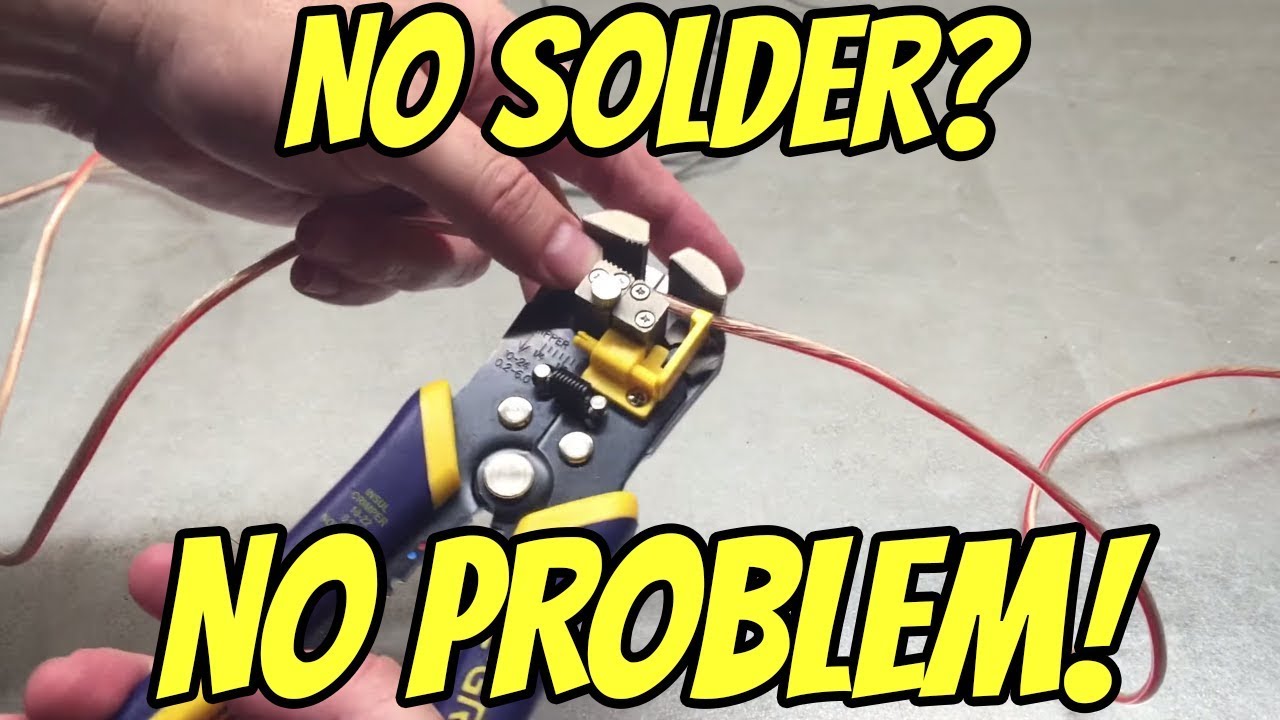

How to solder car speaker wire. A good solution to save space behind the dash would be to get UNINSULATED tubebutt connectors cut out small sections of heat shrink and slide them over one wire end and after crimping wires seal the connection with a heat gun. Twisting wires together and then covering them with heat-shrink wrap or electric tape will suffice for car. Doing so will result in an ineffective joint.

People suggested tinning the stripped speaker wire ends with some kind of solder and then soldering each of the ends to a spade connector. In this video tutorial viewers learn how to solder speaker lead wires. Then remove wire insulation before joining the wires together and place the hot soldering iron over the wires to join them with an iron strip together to the speaker or amplifier terminal.

I might choose to SOLDER the wires from the jack to the speaker terminals as opposed to using a clip-on crimp etc. Simply touch the solder wire to the speaker wire and tabs to solder them. Hold up both ends to form an X shape with the wire facing opposite directions.

Any serious danger of melting the voice coil solder on the other side. A clip can be easliy realigned with a pair of needlenose and and cleaned with some steel wool. Click to expand.

You melt the solder onto the wires to stick them together and as the solder cools it forms a permanent bond. Learn how to correctly solder your speaker wires to ensure a solid connection. Once cool remove any flux residue with a damp rag.

Allow to cool briefly and repeat for the other wire. If there is no sound on both the case you can just solder the corresponding wires. Soldering two wires together requires a soldering iron and solder.