Soldering Iron Tips Wear Out

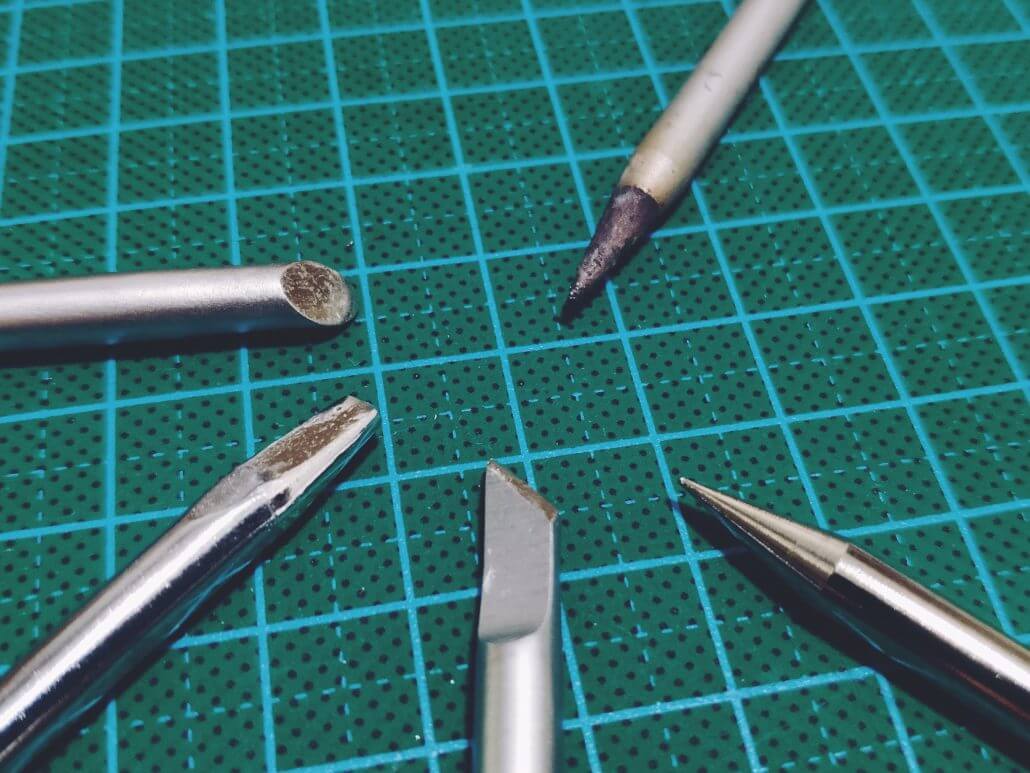

Tips can wear out too - I had an old Radio Shack soldering iron and used it for years and even took a file to the tip to abrade off the bad and carbonized surface but it was very old and worn out.

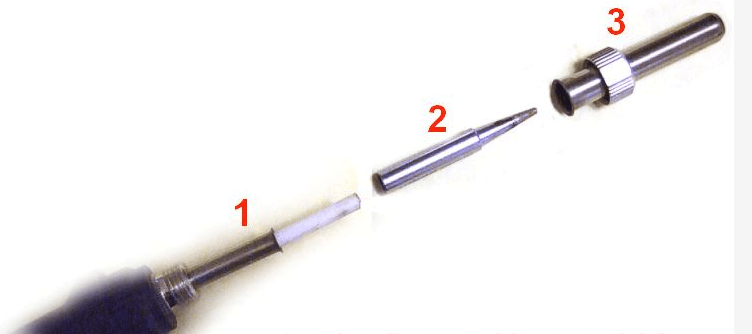

Soldering iron tips wear out. The iron tip will become black after some pads have been soldered. Reply 9 on. This conical-shaped tip is the one that more new users to soldering are likely to imagine because it is widely used and conventional in its shape.

Soldering tips may wear out prematurely especially if you dont know how to use it properly. Its inevitable for soldering tips to wear out over time and need replacing. As any novice handyman would agree improper tip maintenance is the leading cause of soldering iron complications.

Some of these factors include. Oxidation is one of the major culprits of wear out in soldering iron tip. There are various factors that make every soldering iron tip wear out.

This process is used for joining two or more objects together by melting a non-ferrous metal into the joint. Knife or K-series Tips. Solder is then applied to the tip and then it can be used.

It would be best if you considered protecting your tip against oxidation. Metcal JBC Ersa Pace all capable tools. Soldering iron tips wear out over time and unfortunately if your tool fails to transfer heat to the connection point effectively then it must be deemed unreliable and ultimately expendable.

Soldering iron tips are crucial for the soldering process. Do not use the tip tinner on a new or used tip that will still tin properly. When soldering put the iron tip on one side of the metal and touch the solder to the other side of the metal.