How To Solder Car Electrical Wires

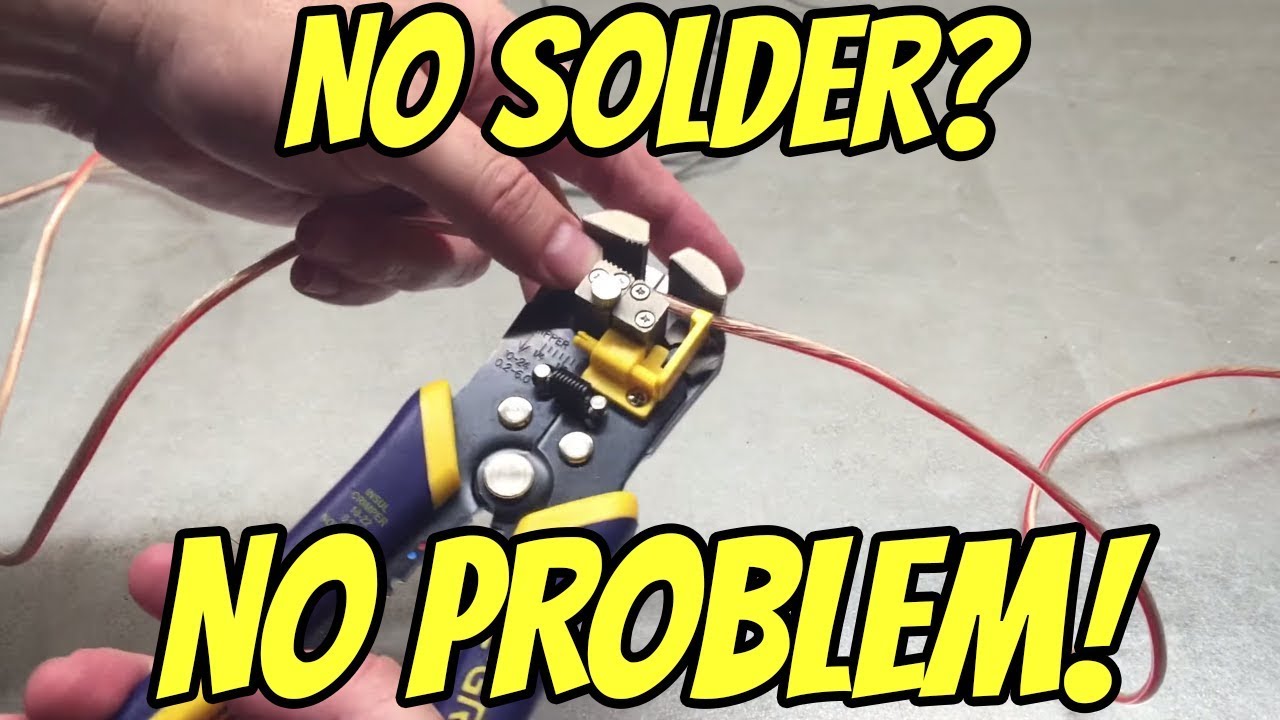

Then use a pair of pliers to push the metal tap down into both wires flush with the body of the connector and snap the cover over the tap.

How to solder car electrical wires. When doing splices clean the wires by scrapingbrushingsanding solder tin the wires to be joined slide clear heat shrink tubing over one wire lay the tinned ends together and touch them with the soldering iron and they will fuse nicely then slide the clear heat shrink tubing over the joint heat shrink one end pack it with petroleum jelly then heat shrink the other end. In this video I will be showing you how to repair the wiring in your car or truck. Wrap one or two inches of solder around the tip while the iron is cold.

The best solution to cover soldered wires is heat shrink tubing and it must be installed BEFORE the soldering is done. The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires. 1 Strip the wires of about 12 in.

Slide the existing wire into the open side of the connector then put the end of the wire you wish to connect to it into the other side. If youre using electrical tape instead apply it once the solder has cooled naturally. Just make sure you use the right size for the wire.

For this example connect a piece of 18 AWG wire to a pre-existing 18 AWG wire. Basic Tips Tricks Tools for Wiring Your Vehicle. Tin Plated Copper Plastic.

Its vital to use a soldering iron that brings the wire up to temperature quickly. I will show you how to solder wires together the right way to seal the solder joint with heat shrink is a must and you also need to make sure you do not have a cold solder. Apply the solder directly to the joined wires rather than the tip.

Tap the end of the 6337 solder on top of the wire splice so the solder melts down into the wires. Once coated sufficiently move the shrink tube and heat it so it makes a snug fit around the wire. Tin coat with solder the soldering tip first.